Projects

Past and ongoing projects

TR4A Cylinder Head - 511695

By far the largest project, and one that is ongoing, has been assistance with the production of the TR4A Cylinder Heads (Part 511695), which can fit any of the 4-pot, wet-linered engines fitted to TR2/3/3A/4/4A, Doretti, Peerless, Italia and certain Morgans, and which are available in cast iron and in alloy through Moss and the companies which it supplies. The Agreement between the SDF and Moss International was a big loan (£14,000 - the majority of the SDF’s funds at that time) to get the project going, and then a pay-back to the SDF on every Head sold after the first 125. The 250 sales figure was passed in late 2008, at which point the original loan was repaid. By the end of 2019, 716 Heads had been sold, and each quarter, around a further ten or more have been sold. However, sales have slowed because of delays caused by the state of the tooling, and the effect of COVID-19. Since the loan was re-paid, and under the terms of the contract, Moss has made a royalty payment to the SDF on each head sold. Pete Cox says that since the heads became available, total sales have been almost exactly two thirds alloy to one third cast iron, and only one Head has ever been returned (from Moss USA) and that was for a leaking core plug, which was rectified and the Head then put back on sale. Generally, the competition people use iron because they have to conform to regulations, and also because it is easier to fit reliably eight oversize valves into iron. This is not an issue with road specification heads, as Moss specifies Stage 2 and 3 only. Race people always do their own thing. Stage 4 would mean fitting both inlet and exhaust ports with oversize valves.

Project Green

The SDF supported the work done by the late Dr Michael Bingley in researching and monitoring the use of an additive which would permit owners of TRs - and other similar vehicles – to use unleaded petrol without the need to modify their engines.

TR4A/5/250 sidelamp/indicator assemblies

The SDF provided a loan to Revington TR (RTR) for reproduction of these assemblies. The contract between SDF and RTR provided for repayment of loan with interest. After a very protracted period of development, these truly excellent reproductions were announced in 2010 and are on sale from RTR at a very competitive price. Unfortunately, there were some minor quality problems which caused delays between prototype and production versions, and Neil Revington, being a stickler for quality (this comes from his background in the aerospace industry) refused to ship until the lamps were to his satisfaction. Eventually, delivery commenced in January 2011

Windscreens, side & rear windows for Peerless/Warwick

The SDF offered a loan to assist with production of these windscreens. In the event, funding was not required as Nigel Cluley and Gary Stretton managed to rescue the tooling when the original supplier went into administration, and the new supplier required nothing other than the tools. In addition, these enterprising fellows managed to arrange for options such as tinted and heated screens, and also production of side and rear windows.

Main and big end bearings for TR5/6 engines

The SDF provided a loan to Revington TR (RTR) for production of these bearings. The contract between SDF and RTR provided for repayment of loan with interest. RTR tracked down the original manufacturer of these bearings and they have been re-introduced to the product line. The range extends from standard size to 0.060" undersize for both Big and Main Bearings. The part numbers follow the original AE numbering system. RTR offers a standard quality bearing set (not AE manufacture) which is adequate for mild operation and the high quality sets (AE manufacture) using the same number suffixed ‘HQ’. Whilst Triumph originally sold bearing shells individually, RTR now only sells sets. Thrust washers are offered only in standard grade as they are subject to light duty and performance improvement does not affect them. Incidentally, these bearings are suitable also for Triumph 2000, 2.5, Vitesse and GT6. Unfortunately, ownership of the manufacturing company changed hands and the new owner decided to discontinue production.

Small Tenax fasteners

From time to time, the SDF has investigated other unobtainable parts, including the small Tenax fasteners found on the sidescreen TRs – the larger Tenax are obtainable and are used nowadays on Morgans (well, of course!). The Tenax fastening consists of a peg, of which there are three variants to permit it to screw into wood and into two types of metal; the one which screws into the windshield surround has to have an especially short thread so as not to crack the screen. The mating part is fitted through a hole cut into the material of hood and tonneau, is in two parts – a part to grip onto the peg and a ring to lock it into the material. This item is particularly complex, and this is the part which always gets damaged by those who don’t know how to fit it over its peg. Despite considerable efforts, the SDF has failed to find a company prepared to produce this rather complex part in comparatively small quantities.

Cantrails for TR2/3/3A hardtop - 802611/802612

The SDF offered a loan to Ian Smith to assist with reproduction of these parts. In the event, funding was not required by Ian as he was able and willing to execute the project himself. His initial production was so widely acclaimed that he was forced to produce a second (and final) run, by the end of which a remarkable 40 sets had been produced.

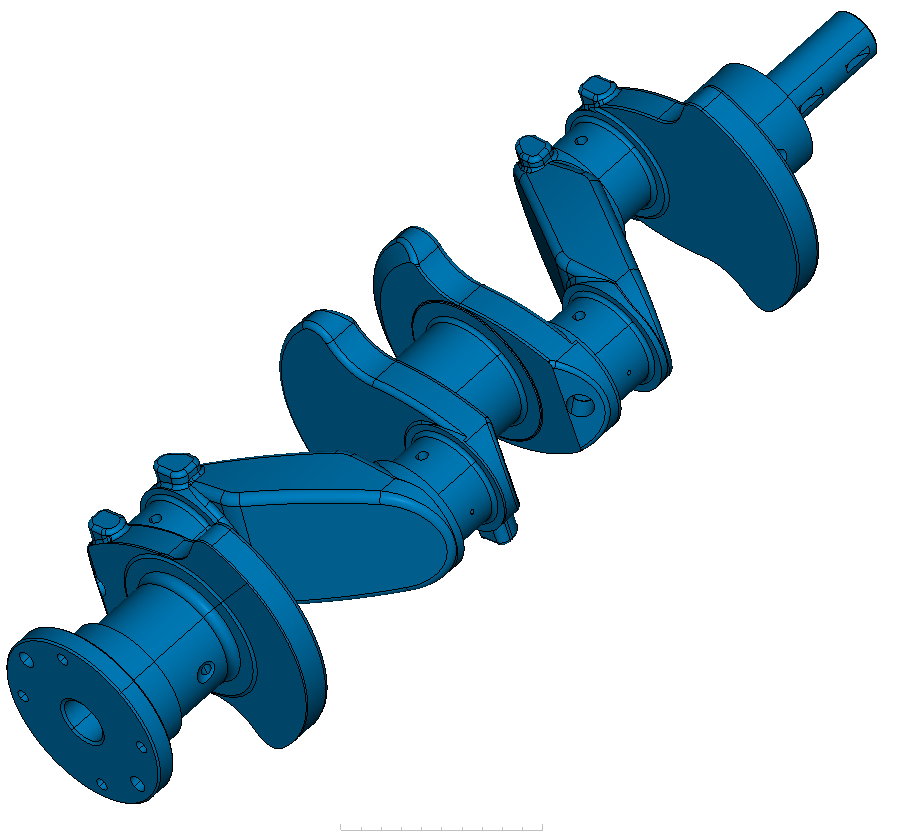

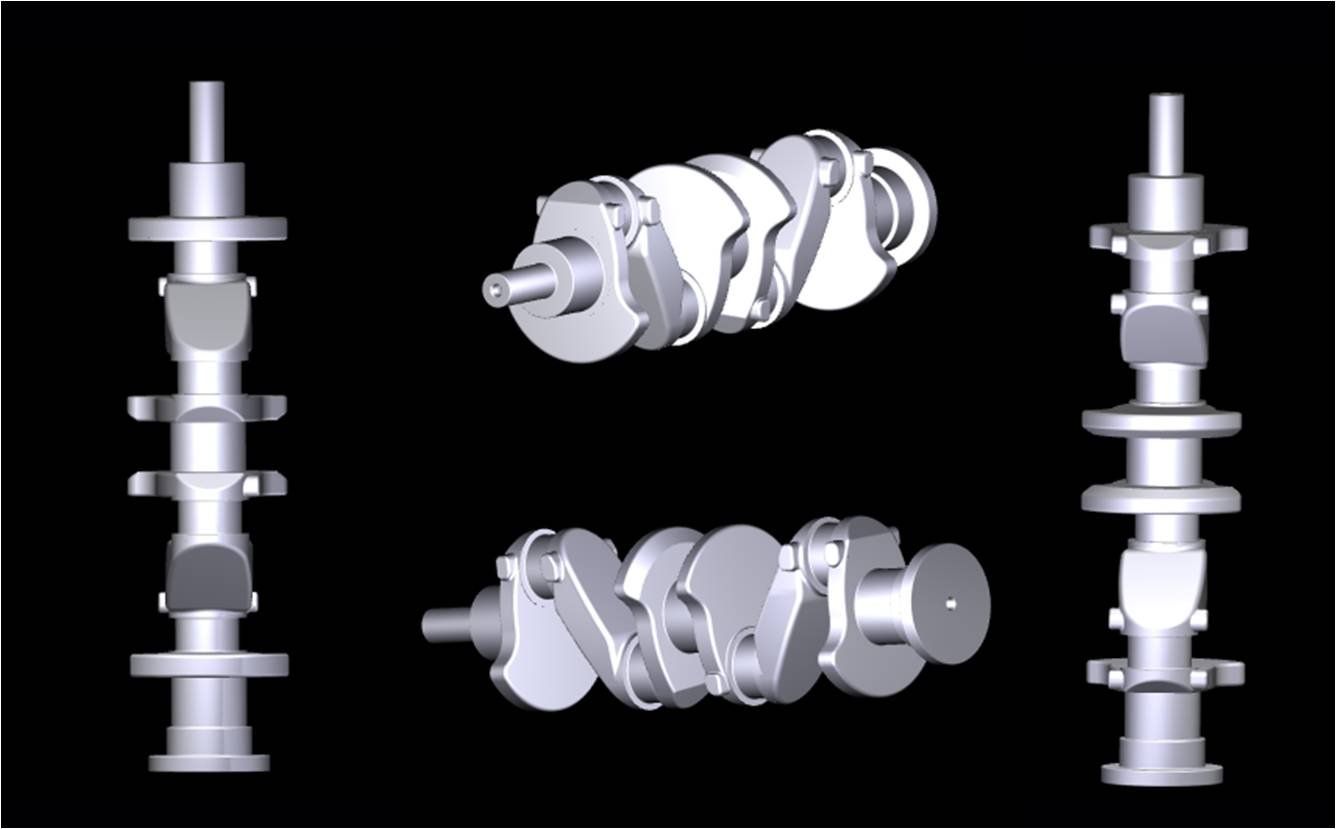

Crankshaft for 4-cylinder, wet-liner engine

A company in India is manufacturing crankshafts which are being used by owners of Ferguson tractors. On investigation by the SDF’s Roger Hogarth and Ian Brown, and Dave McHattie (a qualified metallurgical consultant), the material used in the casting was found to be to the specification used for TR cranks. The Ferguson and TR crank are to the same design, but the oilways differ as the TR is not limited to 2,000 rpm!

The SDF purchased a crank, arranged for machining, and Roger installed it in his TR4A, where it has now covered over 50,000 miles with no problems whatsoever. In addition, the SDF arranged and paid for a second crank to be 3D laser-scanned, reverse-engineered and digital engineering drawings and program detail generated for modern CNC machining, so as to permit remote manufacturing.

A second “prototype” crank was installed in Glen Hewett's MVC575 (the Jabbeke car) as part of Moss's support for his project. This car is now owned by the British Motor Museum at Gaydon, and is displayed there.

Following the successful proving of the prototypes, Moss is having the basic machining undertaken in India, but the machining for bearings, oilways etc. is being undertaken in the UK to the engineering data – this should ensure that the finished article will be of the same quality as the cranks produced by Triumph from the 1950s onwards. Three cranks were successfully completed in 2019, and Moss is moving forward with finishing, costing and marketing. Moss reimbursed the SDF for the parts procured and the work undertaken to bring this project to a successful conclusion.

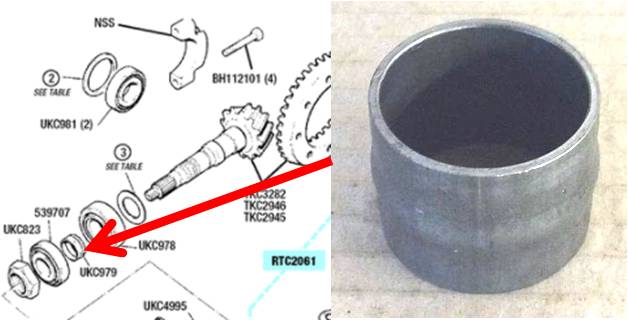

TR7 & TR7V8 Collapsible Spacer - UKC979

After conducting discussions with all the major suppliers, only one item, the collapsible spacer (UKC979) fitted to the TR7 / TR8 Rear Axle Pinion Bearing, was identified as unavaiIable. The SDF managed to obtain a good, used specimen, identified the material and, in conjunction with Rimmers, found a company which was able to reproduce the part. It is now undergoing the development process.

TR7 & TR7V8 Body Panels

The late Jim Pickard, the TR Register’s Wedge Team Leader, initiated liaison with the TRDC with a view to having the front assembly reproduced, this being the part which incorporates the holes for the lamps, and one of the first parts of the car to rot away &/or be damaged. The TR SDF had a meeting with the TRDC at Gaydon, but Jim was unable to attend owing to his illness. The company selected for this work is Ex Pressed Steel, and Ian Gibson visited the works, returning with very a favourable impression. The company manufactures in batches of 10, so there needed to be a guarantee that this number would be sold – hence the collaboration with the TR SDF because the TRDC does not have such funding available. Having reached agreement, it was hoped that this assembly, which consists of two pressings, would be available by the end of 2020, although there is likely to be a delay resulting from the restrictions imposed in the light of COVID-19.

The TR SDF welcomes this opportunity to work with the TRDC and if this project proves successful, repair sections for the lower parts of the wings are likely to be the next joint project.

Steel Wheels

Supplies of 4½J and 5J steel wheels in good condition for TR2 to TR5 seem to be running low, and especially as far as the competition-minded members are concerned. The TR SDF is trying to determine the magnitude of demand for each size, and is bearing in mind that competitors have no need for the 3 pips to which the trim fixes, but those with road-going cars almost certainly would require the fixings. The TR SDF approached the original manufacturer, but eventually this proved to be a dead end and so one of the major and well-known TR suppliers has been approached and it is hoped that batch production may be organized at some future date.

Early TR2 Rear Lamp bezel

This rear light, fitted to pre-TS1307 TR2s, uses the normal L471 backplate, 18/6 watt bulb, the same lens and the same two chrome screws to retain the bezel and the lens. The two things that differ are the bezel and its gasket. As far as we know, this arose simply because Lucas failed to have their then new rear light (the L549, used on all later sidescreen cars) ready for start of TR2 production. When reflectors became mandatory in 1953/4, they were dangled below the lamp on each side (see page 62 of Bill Piggott’s tome).

Thanks to Christoph Mathey and Pete Cox (again!), the TR SDF has available a very limited number of sets (pairs) of the Chrome Bezels 572249. These are of high quality and finished in chrome – as can be seen in the photo, which shows a bezel sitting on a Lucas 471 lens alongside an upturned bezel. Unfortunately, it has not been possible to find anyone prepared to produce the gaskets (572245).

Re-build of TS2

TS2 was the second TR2 ever made and the first right-hand drive TR. For the project, the SDF made an interest-free loan of £5,000 to the TR Register (TRR) to get the restoration going, in addition to an outright gift of £1,000. From the amount of interest shown in TS2, and its continuing publicity value to the TRR, these have been very worthwhile initiatives.

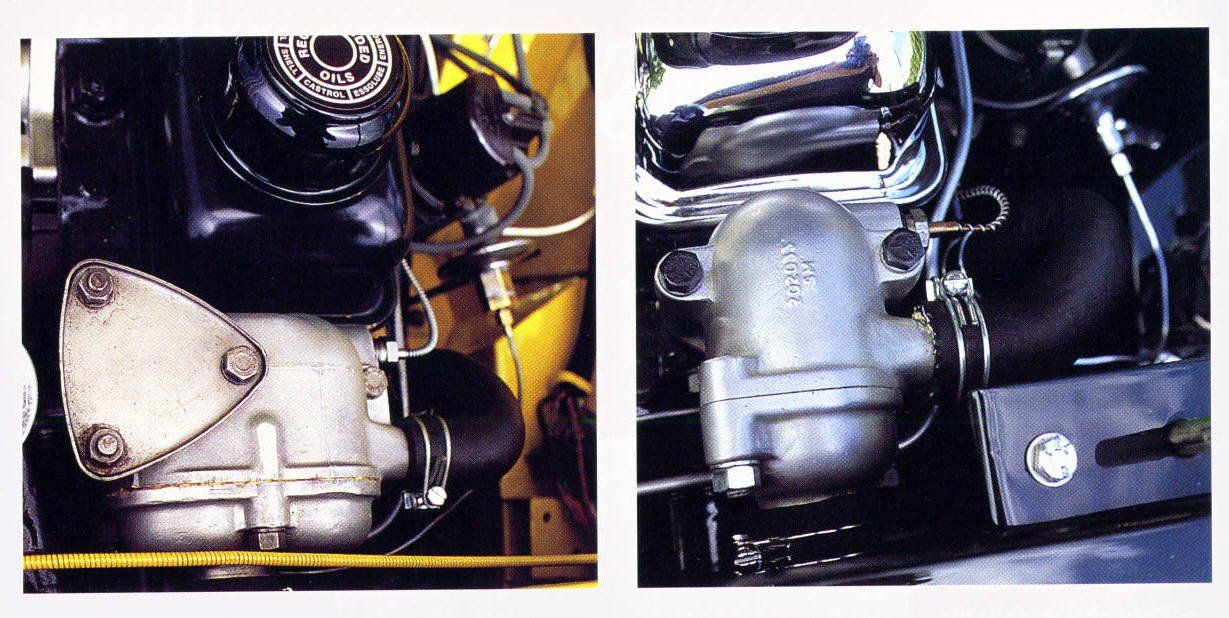

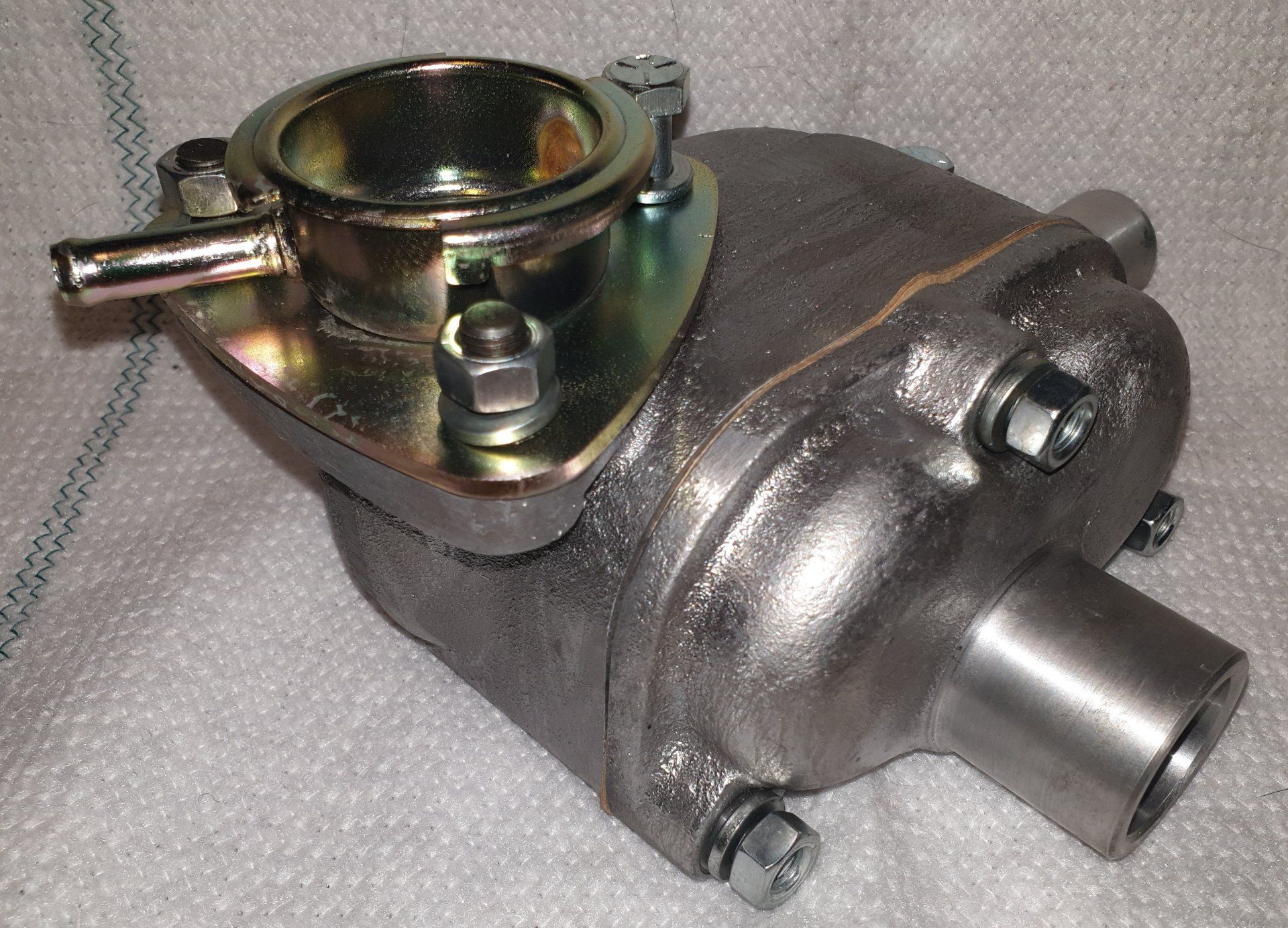

Early TR2 Thermostat Housing

The early TR2s feature a couple of items which have not been available for years, one being the double thermostat housing fitted before TS1201E, Part 201522/105584. This assembly is pictured in the left shot on page 72 of Bill Piggott’s invaluable tome, “Original Triumph TR2/3/3A”, but depicts the housing with a blanking plate in place of a filler cap. A filler was fitted to the housing on TS1 and TS2, the first left-hand and right-hand drive TR2s, but it was found unsatisfactory because the top of the filler lay below the top of the radiator. Thereafter, a blanking plate was fitted to the housing and the radiator was provided with a rearward- and upward-facing projection to bring the filler above the top of the radiator. Because these housings are well over 60 years old and were cast from decidedly inferior material, many developed leaks, and, even if they didn’t leak, some early owners decided to replace them with the later and more familiar unit, depicted in the right shot (Part 202033/203781).

As it was clear that there was a demand for the original housing amongst those keen on originality, the SDF decided to investigate re-manufacture, in superior materials and to a high standard. This project has been the baby of Christoph Mathey (in Switzerland) and Pete Cox, to whom the SDF owes a deal of thanks for doggedly working for more than two years to bring matters to a most satisfactory conclusion.

The new housings were cast in aluminium, which then was machined. The filler/neck plate is zinc plated; the bolts, nuts and lock washers are bright zinc plated.

The studs are not coated, but only the tips are visible. The units are complete with their 2 gaskets, studs, nuts, bolts and washers, and are boxed. In addition, an extra two sets of (spare) gaskets are supplied in a small plastic bag in each box, plus (for those who may not wish to utilise the filler/overflow) a drilled and plated triangular blanking plate as shown in the photo in Bill’s book. Thermostat and radiator cap are not included because purchasers will have these already.

The purchaser can decide whether to fit the housing as supplied, making the car appear as TS1 and TS2 were produced originally, or remove the filler/overflow and fit the included triangular blanking plate, as shown in the first photo from Bill’s book.

This reproduction is of a quality far exceeding that of the original, and can be expected to have a life of at least a hundred years, which should be good news to the great grandchildren of current owners! Production has been limited to 50 units, and these are on sale as Part Number 201522KIT – it will be first come, first served, and when they’ve gone .....

The units are available from Pete and Tom Cox at Pete Cox Sportscars

Web: https://petecoxsportscars.co.uk

Email: enquiry@petecoxsportscars.co.uk

TR4 Left-hand lower crash pad grab rail - 805757/808732

This refers to Part 805757 (pad, crash assembly, facia bottom, LH, RH steering!) fitted at the base of the dashboard on right-hand drive TR4s, and has long been unobtainable. Unlike the grab rail on the sidescreen cars, which is fitted to remove the passenger’s teeth in the event of a collision, the TR4 item is padded! The SDF has obtained a pristine original and is working with a major UK supplier in reverse engineering the product. A second item has been despatched across to the USA, via a posting on the TR Register’s Forum, to a company interested in investigating remanufacturing the item.

Reveal Moulding for early TR2 - 603177

Some TR2s – and no one is able to say how many – were fitted with a Reveal Moulding to the lower part of the air intake. The TR3 received a 2-part moulding, 604338/554204. Although listed in the Parts Book, neither is depicted, but they are shown in the Moss catalogue. Thanks to the generosity of Irishman John Reilly, the SDF has been gifted a used 603177 and will be investigating the possibility or reproducing this rather odd and unwieldy item. As it happens, Ian Gibson’s TR2 has always had this moulding, which should be helpful.

Note: All loans mentioned herein have been re-paid in accordance with the terms of the individual contract.

Projects under investigation

Over the years, the SDF has received numerous suggestions for projects, but the majority have turned out to be items which were already available from Moss, Revington and other suppliers. So, forecasting is difficult because, on the whole, the TR SDF reacts to reported problems on availability, such as those projects listed above. However, with feedback from PQI, TR related forums, the TR Register’s magazine TR Action, and the TR Drivers Club (TRDC), and with the assistance of Pete Cox, Tony Sheach and some others, it might be possible to foresee some future shortages &/or problems.

TR7 & TR7V8 Parts

The TR SDF has conducted discussions with the major suppliers in order to determine whether reported shortages are real or imaginary. The model has a unit construction body and it is obvious that, bearing in mind the value of a top-notch car and the cost of creating a shell, no one would be prepared to contemplate such an exercise. Where bodywork is in a bad state, it is a matter of fabricating patches and doing the best job possible to ensure the integrity of the whole structure, but the TR SDF is co-operating with the TR Drivers Club (TRDC) in order that an important panel assembly may be reproduced.

The quality of most of the bearings in the market supplied to TR7 owners were not to OE specifications, but negotiations with Rimmer Bros. has established that a range of OE Timken bearings is now offered alongside cheaper options.

Thus far, only one item has been identified as unavailable, the collapsible spacer (UKC979) fitted to the TR7 / TR8 Rear Axle Pinion Bearing. The TR SDF managed to obtain a good, used specimen, identified the material and sought a company which could produce a batch. Rimmer Bros took up the challenge. Click here for more details.

Worthy of Investigation

There follows a list of items which we will research further to gauge availability, alternatives, viability of project etc. Most of these items are comparatively cheap to produce, but good second-hand versions are expensive.

- TR4 centre switch panels in plastic – Reinforcement, switch mounting 610818 (569926 earlier) – both NCA on Moss.

- DR3a wiper motor internal parts, rubber bits etc

- TR4/4A dashboard backs in steel – Facia panel assembly, RH steering 903199. Essential to get the "D" shaped holes reproduced correctly. (902315 earlier; 569380, 903512, 569383 later). All NCA on Moss.

- Switch bezels in stainless steel.

- TR2/3/3A windscreen mounting – although Dzus and screw fixing types were used, Parts book lists only one number for each side Plate assembly, stanchion guide 552818 (LH) & 552819 (RH). SDF has a sample.

- Chrome sidescreen retaining strip (702433 - and not handed), which was offered from TS8637 as part of "Grand Touring Cars Conversion Kit". Not pictured in Parts Manual.

- TR3/3/4 handbrake lever 131231. Both TR2/3 and TR4 levers NCA on Moss – use 2nd hand.

- TR2/3/4 riveted road wheels.

- TR4A grilles 904120 available from Moss.

- TR250/TR5 grilles – 812300 available from Moss.

- TR4 roof in alloy 566994, TR4A 903979, TR5 903978 available from Revington in alloy and fibreglass.

- TR5/early TR6 RHD steel dashboard backs 907668 available from Revington

- TR4 gear lever grommets - Grommet, gear lever 705913 (but listed by Moss as Gaiter, gear lever, rubber) available from Moss.

- TR2/3/3A hardtop alloy finishers - Plate, tonneau capping 602938 (listed by Moss as Plate, tonneau capping, side) available from Moss.

- Gear levers TR2/3/3A – Lever assembly 3 versions: 107888 + 125059, 109042, 112447 (112447 available from Moss).

- TR2/3/3A RHD dashboard backs in steel – Facia panel RHS 901774. Moss lists 900381, but as Out of Stock.

Parts Quality Initiative (PQI)

The supply of parts is essential to preserving and keeping Triumph TRs on the road.

Currently, the entire range of Triumph TR sports cars is very well serviced by a variety of suppliers of parts and accessories. In fact, the situation is possibly healthier today than at any time since individual TR models ceased production. The huge majority of TR parts supplied and transactions completed across the country are more than satisfactory. However, there are occasions when patterns emerge around issues with certain components. Our aim is to build a structure in which parts quality concerns can be managed with the specialist suppliers such that both we and they may take appropriate actions to keep our classic Triumph TRs on the road, reliably and safely.

The mission of the Parts Quality Initiative (PQI), which operates under the umbrella of the TR SDF, is to achieve the following:

"To help identify major parts related issues through the use of feedback from TR owners. To accumulate, compile and analyse factual information in order to work with suppliers to identify and replace problem components in their ranges. This will enable the suppliers continually to improve their offerings to TR owners."

Clearly, we require the assistance of owners in this initiative. However we do expect that any transactions will have been entered and completed in “good faith” by both parties, with constructive dialogue and efforts made, and recorded if necessary, to resolve individual issues and problems.

The PQI is not aligned to individual problems; it will remain focused on broad quality issues and represents a natural progression for the TR SDF. In order to allow the main focus of the original TR SDF team to remain with finding solutions to the lack of availability of critical parts, the team has been enlarged to include Ian Brown and Roger Hogarth, with support, where required, from Stuart Edwards. These individuals will be specifically looking at the issue of parts quality, and will need assistance from other owners with suitable experience and knowledge.

Ian Brown and Roger Hogarth have been in face-to-face contact with all the major suppliers, and in each case the reaction to the PQI initiative has been a strong welcome.

For a list of PQI investigations since 2014, please click here.

To communicate with the Parts Quality Initiative, TR owners are asked, in the first instance, to complete the PQI Report Form below. The form asks questions relating to product issues and what dialogue has taken place with the supplier. The forms are collated and patterns amongst the responses identified for action. If we feel we can help with the issue we will contact you to ask for photos of the part in question and further supporting evidence of the problem. By using this form to contact the TR SDF you consent to us storing and processing the information you supply in accordance with our policies.